How to Identify and Measure Synchronous (Timing) Belts

.png)

In an ideal situation, you can identify the belt you have by its markings alone. Typically, those are alphanumeric labels that identify the belt's specifications, often describing the most important dimensions critical to properly identify them.

(In another article, we discussed how you can identify a v-belt.)

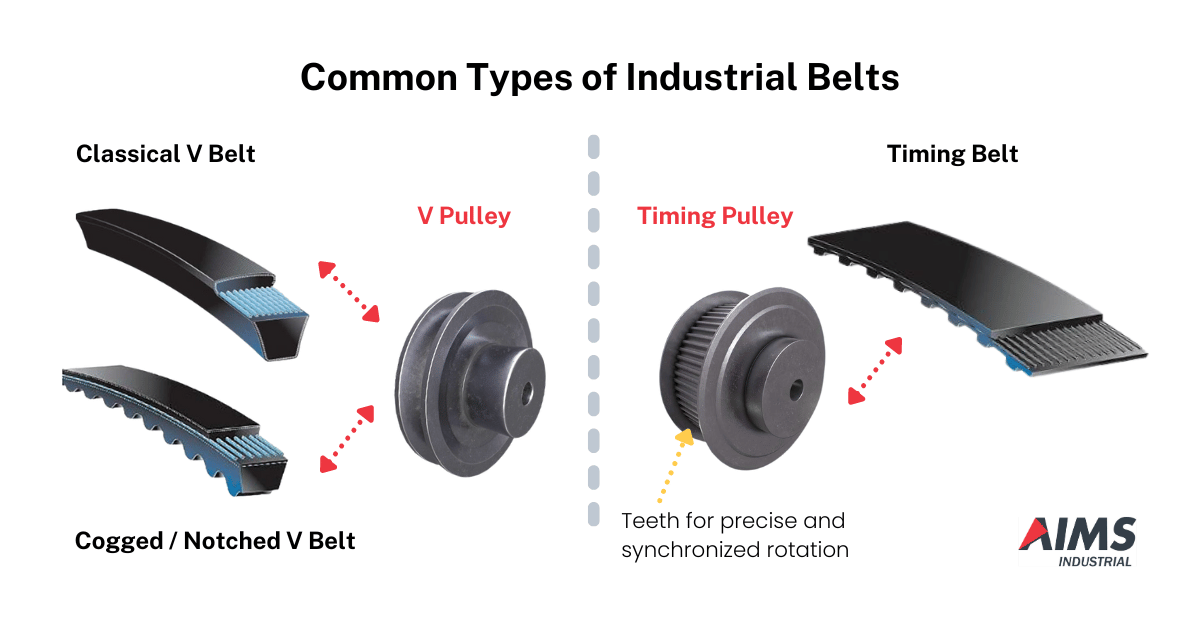

Important: If your pulley has teeth, then you indeed have a synchronous timing belt, which should not be mistaken for cogged belts -- who also appear like they have "teeth" but are just actually cogs (notches) -- such as these banded-narrow, classical and narrow-section cogged belts.

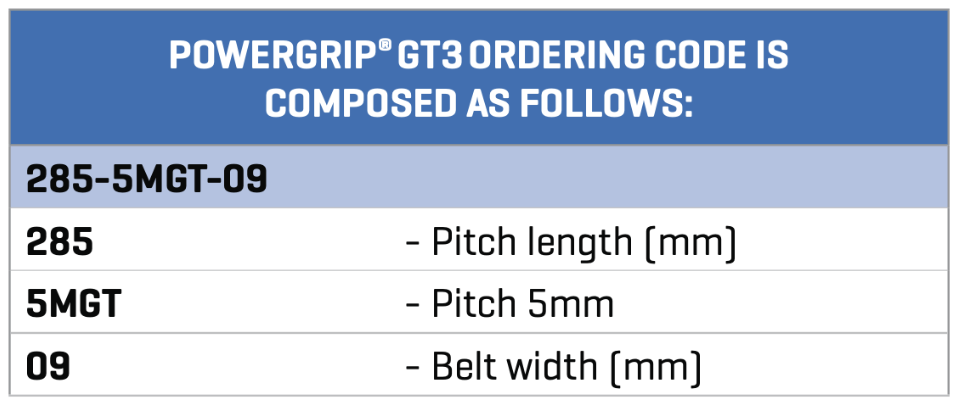

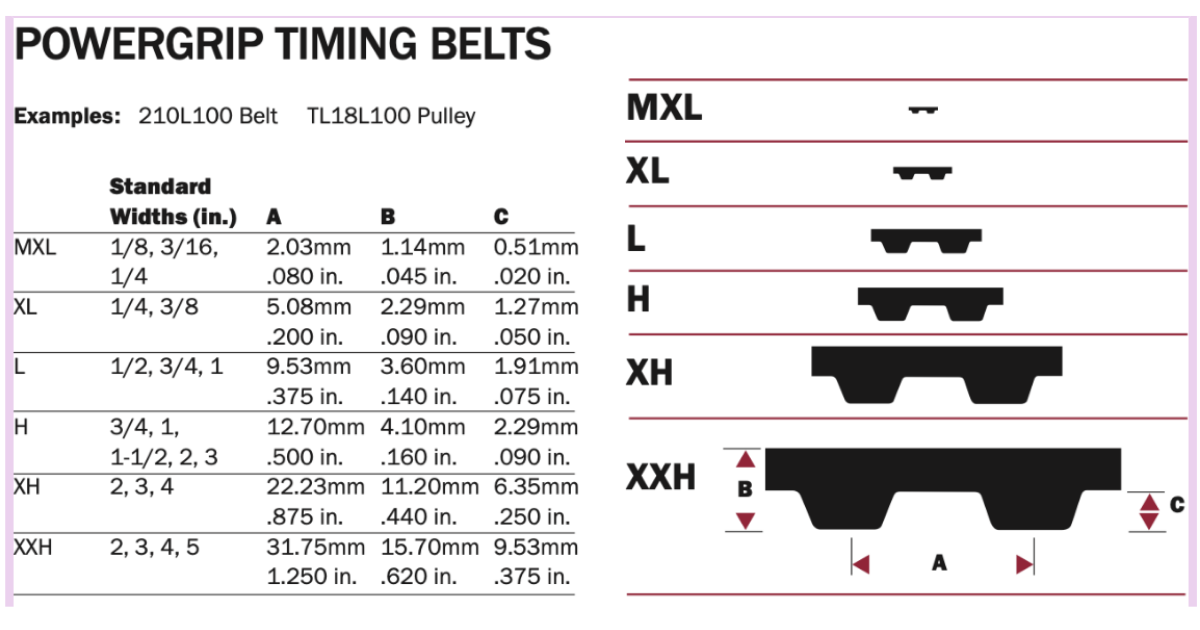

For example, in Gates nomenclature, in their PowerGrip range, you’ll see a marking that designates the belt’s pitch length, pitch and tooth profile (the letters), and the width.

(Image taken from the Gates Industrial Power Transmission Catalog)

Note:

- This applies to both single-side and double-sided synchronous belts.

- Nomenclature and order may vary by manufacturer.

You may, however, be in a situation where you don’t have access to that information for many reasons, such as:

- The belt is still installed in the pulley and there’s no way you can see the markings.

- The belt is already snapped and torn.

- The markings are too faded or dirtied to be read.

In this case, you may have to manually figure out your belt specifications. We hope this article points you in the right direction.

Here are the 3 key identifiers you need to determine to order the belt:

1. What is the tooth profile of the belt?

1. What is the tooth profile of the belt?

This is the most important identifying factor of synchronous belts, so it’s important to get this right. If you get the wrong profile, it may not fit the pulley at all and, if it does, it will wear out very quickly.

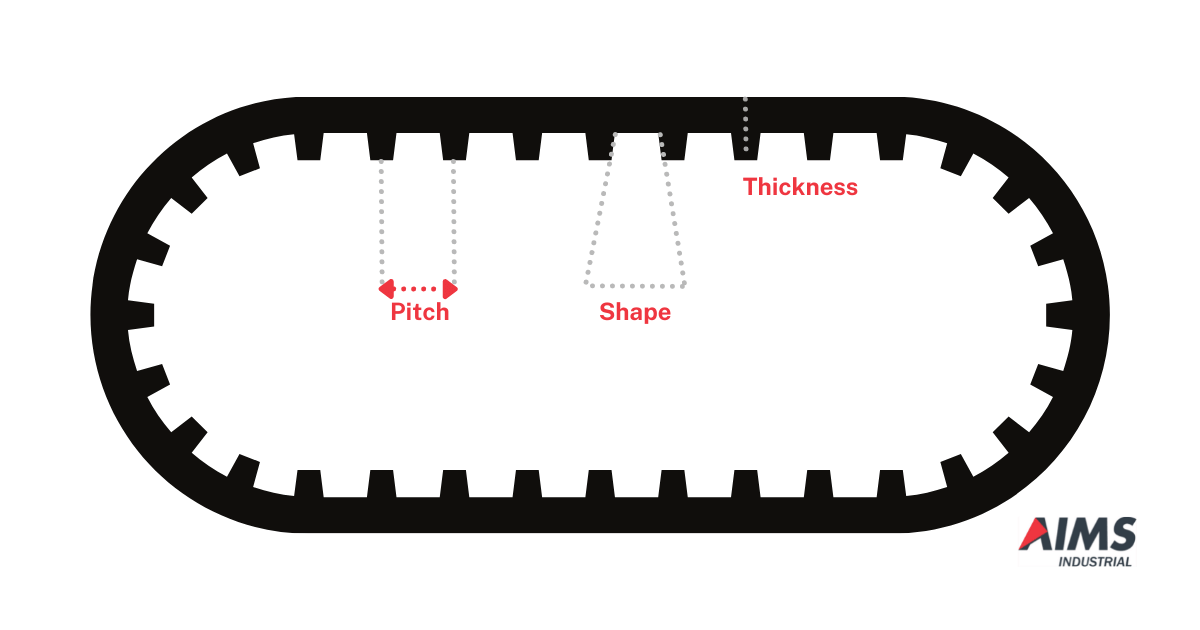

You can tell the profile of the belt by its pitch and shape. You can also measure the thickness as a cross-check.

Pitch

- This is the “centre-to-centre" distance between two adjacent teeth.

- To get this number, measure the distance between the middle of one tooth, to the middle of the adjacent tooth.

- Imperial vs Metric: This is another key factor in finding the type of belt you have, so it’s equally important to get this right.

Important: When manually measuring the pitch, please make sure to use the metric system (eg. by millimeters), as we often do here in Australia. Otherwise, let us know that you’re giving us the measurement in imperial, so we can help you work out its metric equivalent.

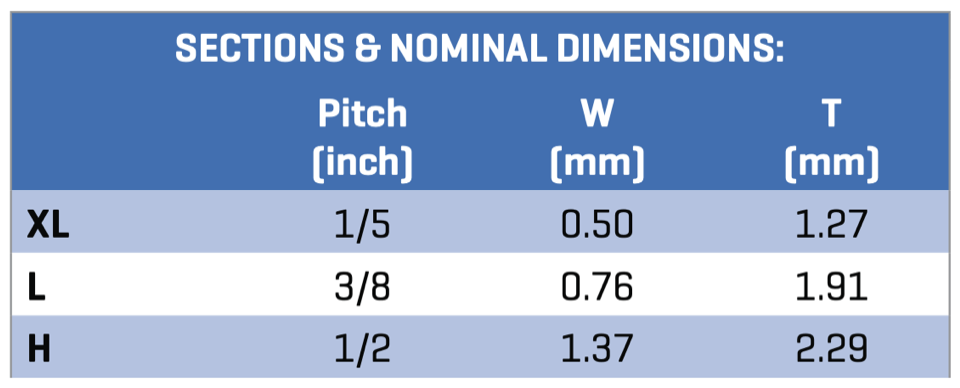

In this sample reference from the Gates PowerGrip range, you’ll see the pitch is indicated in imperial units (eg. 1/5 inch), as it would be typically written.

(Image taken from the Gates Industrial Power Transmission Catalog)

Here’s another reference from the Gates PowerGrip timing belt range. Note that this range is imperial but, for ease, dimensions are shown in both imperial and metric units. In this illustration, label A is the pitch.

(Image taken from the Gates Industrial Power Transmission Catalog)

Aside from the belt, don’t forget to check the pulleys for any markings too. The pulley won’t give you everything you need to order the belt but they often have the pitch/profile printed on them. If so, this will make life a lot easier. It also helps a lot because, occasionally, we find that someone has previously fitted the wrong belt, so checking the pulley is a great way of ensuring you’re getting the right belt.

Shape

- This is how the angles of the peaks and valleys in between the teeth look like, as well as the shape of the tooth. Some belts have rounded teeth, whilst others are quite ‘square’ or trapezoidal. Some people refer to this as the tooth form.

- Metric belts usually have rounded teeth, while imperial belts have trapezoidal ones, but keep in mind that is not always the case.

- If you’re having trouble and need our help identifying the belt, we won’t need the exact angle of the shape, but as always, it will be helpful if you can send a photo of the actual belt that needs replacing, as well as the pitch as accurately measured as possible.

Thickness

- Aside from the shape, this value will help us get a better understanding of the belt you have. Although it’s more challenging to get this exactly right considering the wear on the belt.

Warning:

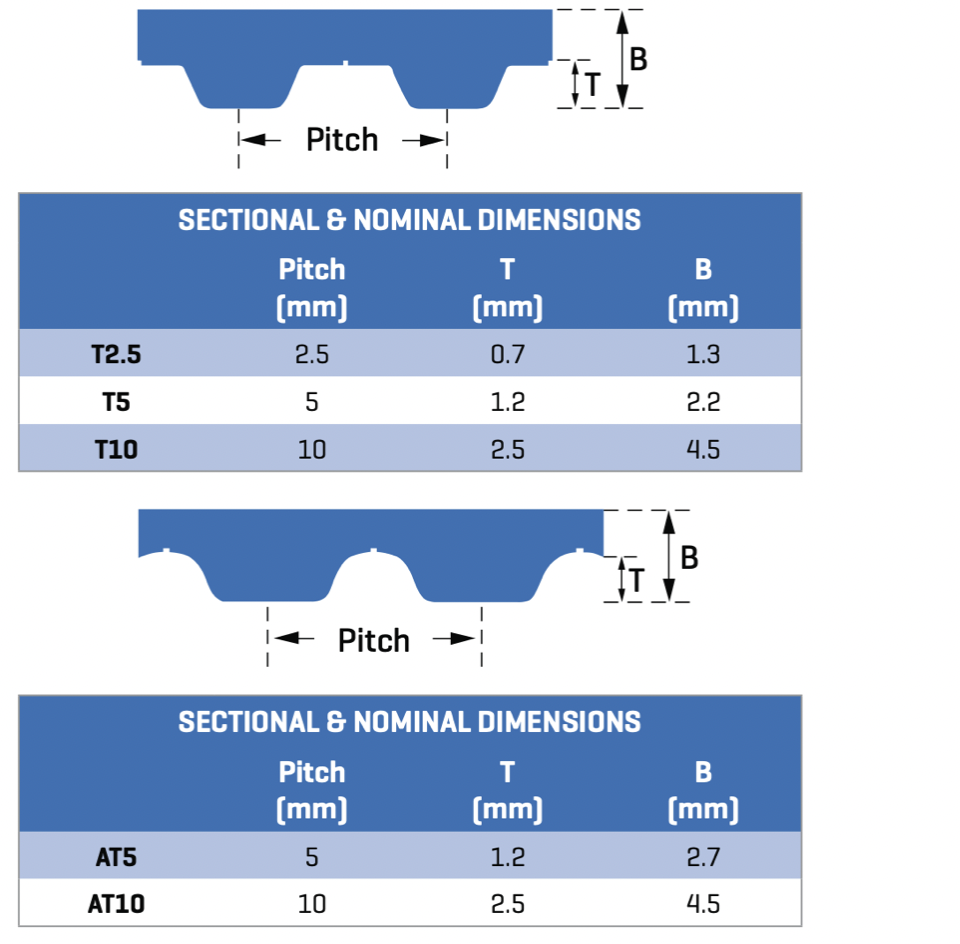

- Don’t be confused by the T and AT profiles (eg T10 & AT10). As you can see in the illustration below, the Ts are more trapezoidal, while the ATs are more rounded. Both, of course, have the same Pitch (eg. 10mm) but the shape is very different. If in doubt, send us a photo of the actual belt and we’ll help you figure it out.

(Image taken from the Gates Industrial Power Transmission Catalog)

2. What is the length?

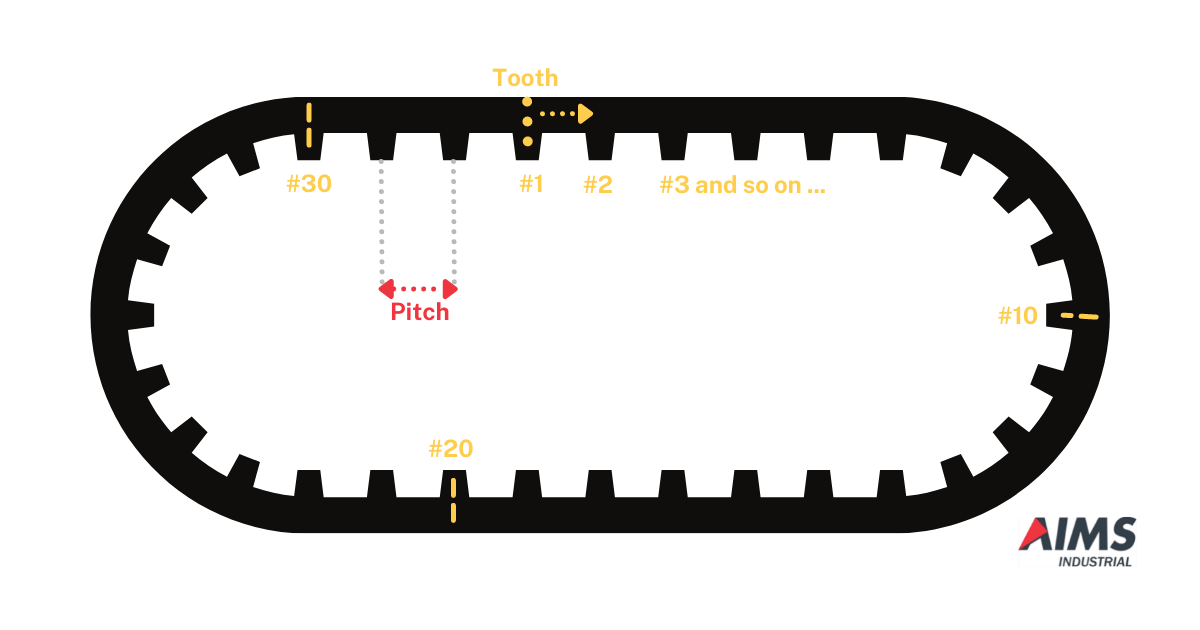

Sometimes also referred to as pitch length, this is the total (circumferential) length of the belt, as measured along the pitch line. Put simply, this is the pitch (see #1) multiplied by the number of teeth the belt has.

For example, if your belt has a pitch of 10 mm and 32 teeth, then your pitch length is 320 mm.

Tip:

- Mark the tooth where you are going to start counting, and count carefully from there.

- Some even make subtle marks for every 10th tooth, so it’s easy to go back (and verify) in case you lose count.

- If possible, get someone else to count as well and then cross-check. We do that with every belt to avoid errors. If you don’t have someone else to check it, then count it yourself 2 or 3 times to ensure you have it right.

Special case for imperial belts:

- Imperial belt pitch lengths are marked in imperial by 1/100 or 1/10 of an inch (in decimal inches). Naturally larger belts are measured in 1/10 and smaller in 1/100. Here is an example from Gates:

.png)

That means it’s 2.88 inches long and it’s listed this way in the table where you’ll see its metric equivalent of 73.15 mm:

.png)

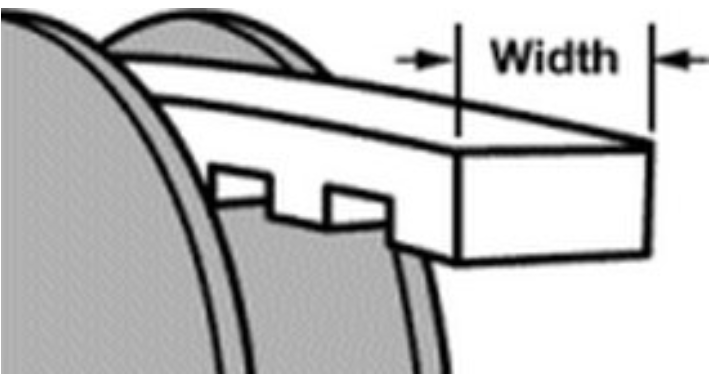

3. What is the width?

Measuring this is pretty much straightforward. Just bear in mind that the belt may be a little worn.

(Timing belt 3D view illustration courtesy of Pfifer)

Special case for imperial belts:

- Imperial belt widths are identified in decimal inches, as in the previous example by Gates:

.png)

In this example, the belt width is 0.19 inches. Furthermore, if it were 050, then that would be 0.50 inches. Or 0.75 inches. 100 would be 1 inch and so on.

Other factors to consider

In addition to those three questions, we may occasionally need to confirm the following:

- What’s the application? Even when two belts are dimensionally the same, one may be stronger than another and therefore designed to withstand heavier loads (eg. for systems with forced induction mechanisms such as superchargers).

- Are you sure it’s not a cogged V belt? The 'cog's or notches in cogged V belts make it "look like they have teeth", but they actually go into a pulley with no teeth. To emphasise, if the pulleys have no teeth, then it isn’t a timing belt. It is then typically a cogged V belt or, occasionally, a Variable Speed belt.

- What is the belt made of? Most are made of rubber, while some are made of aramid, neoprene, carbon fibre, polycarbonate or polyurethane. Some are strong enough they can replace chains, provided they can fit in the proper (or appropriately converted) sprockets.

For more information, you can refer to these catalogues by Gates:

- Gates Belts ID Chart

- Gates Industrial Power Transmission Catalogue

- Gates High Performance Belt Drives Catalogue

Conclusion

- Measure your belt pitch. From there, identify your tooth profile.

- Measure your belt length by counting the number of teeth and multiplying it by the pitch.

- Measure your belt width.

In addition, it’s best if you can identify:

- The intended application

- The material of the belt

If in doubt, just reach out to us and we’ll help you figure it out. It would be helpful if you can include pictures of the actual belt you want to replace and any measurements you’ve taken.

AIMS' Note on Safe Use of Belt-Driven Systems

- Power down: Before any inspection, maintenance, or adjustment, make sure to completely shut down the power to the machine and apply a lockout/tagout (LOTO) device to prevent accidental restarts.

- Right belt for the system: Keep in mind that v-belts (especially cogged / notched / wrapped belts) are different from synchronous /timing / ‘toothed’ belts. Some mistake the cogs for teeth but remember that cogged belts run on V-shaped pulleys that do not have teeth. Are you operating where flammable substances are present? Maybe you need fire-resistant anti-static (FRAS) belts – or maybe heat-resistant and oil-resistant belts will do. We compared them in this FAQ.

- Safe attire: Avoid loose clothing, jewelry and long hair that could get caught in the moving parts. Ensure proper fit of workwear without compromising comfort, dexterity and protection. Tie back long hair and secure loose items.

- Safeguards in place: Never operate a belt-driven system with the guards removed or bypassed. These guards are there for your protection.

- Maintenance and replacement: Regularly inspect belts and pulleys for wear and tear. Maintain proper belt tension and alignment as specified by the manufacturer. When replacing the belt, make sure you get the proper fit and measurement of the system. These accessories and maintenance kits (eg alignment tools, belt measurers, pulley gauge sets, spacers, tensioners etc) come in handy.

- Cleanliness: Keep the area around belt drives free of debris and clutter that could get caught or cause a fire hazard.

(Refer to our content library's sub-index of articles about belt-driven systems and electric motors for more information.)

.png)