How to Identify and Measure V Belts

.png)

At this point, we are assuming that you have identified the belt but need to ensure you get the right length.

(In another article, we discussed how you can identify and measure synchronous (timing) belts.)

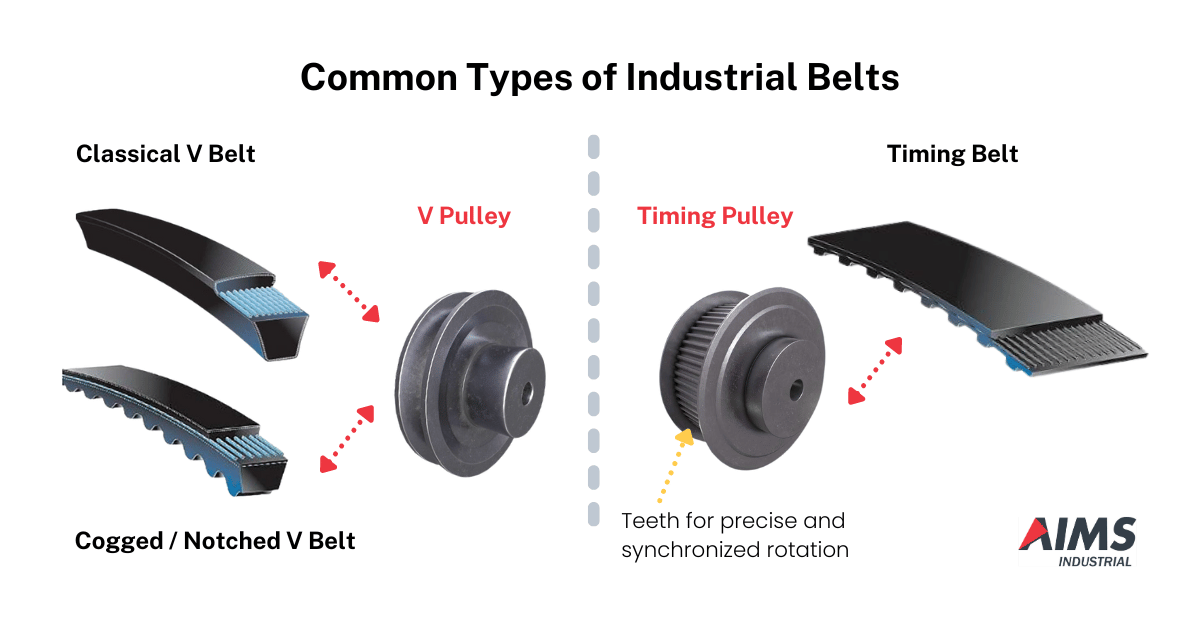

Important: If your pulley has teeth, then you probably have a synchronous timing belt, which should not be mistaken for cogged belts -- who also appear like they have "teeth" but are just actually cogs (notches) -- such as these banded-narrow, classical and narrow-section cogged belts.

We are dealing here with V belts, which are power transmission belts that have a V shape. They may be cogged (notched) or wrapped. They are run on V shaped pulleys that do not have teeth.

We’ve updated this article for timeliness, clarity and depth, and it may contain technical details, terms and jargon.

- Definition of different belt lengths

- When to use which diameter

- How to measure classical V belts

- How to measure narrow section V belts

- The carpenter’s golden rule

Definition of different belt lengths

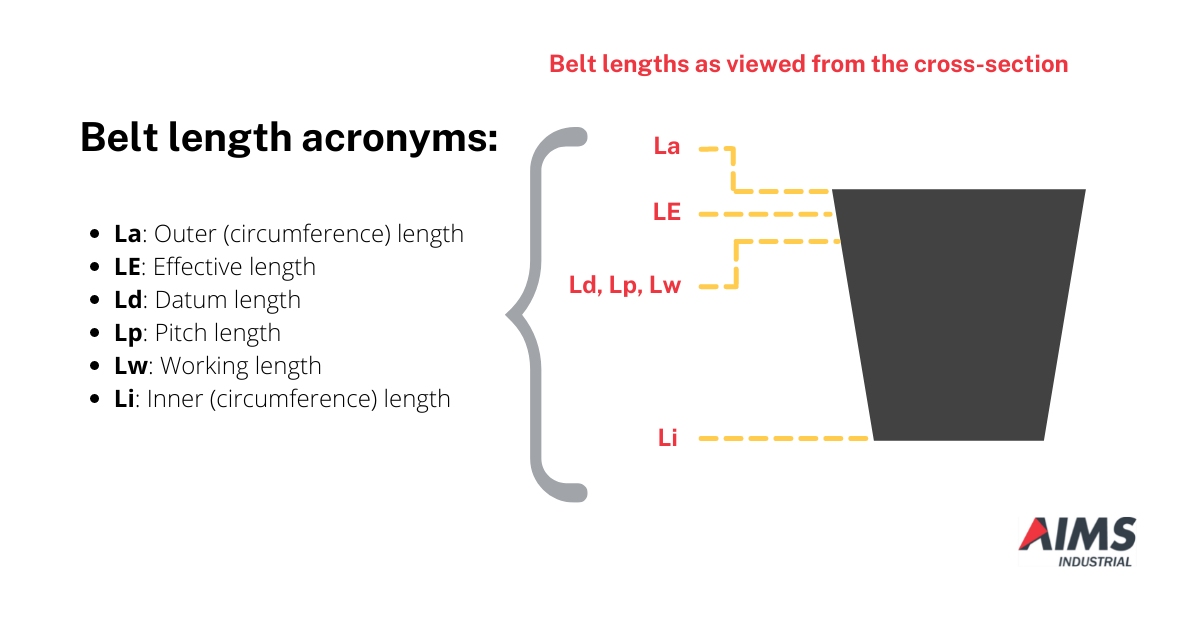

According to Gates, in their GatesFacts Technical Information Library, figuring out the belt length can be “confusing” especially when people don’t always refer to the same terms. For clarity, here are the various lengths and how they are described (directly taken from Gates):

- Outside Belt Length: The outside length of a belt is usually measured with a tape under no tension. Its validity is questionable since some belts have an arched top whereas others are flat. This would give different readings for the two belts. It can be used only as an approximation.

- Inside Belt Length: The inside length is measured with flat pulleys (not v-pulleys) and a tape measure. As with the outside length, the inside length varies with the manufacturer. This length should not be used.

- Note: As clarified with Gates, if you know the diameter of the flat pulleys and the center distance between them, then you can calculate belt length. This will be equal to half the circumference of each pulley plus double the length between the shaft centres.

- Note: As clarified with Gates, if you know the diameter of the flat pulleys and the center distance between them, then you can calculate belt length. This will be equal to half the circumference of each pulley plus double the length between the shaft centres.

- Belt Pitch (Datum) Length: The pitch length of a belt is the length at the pitch diameter of the sheaves being used. Classical industrial belts are specified in terms of pitch length. The pitch length is obtained by adding the pitch circumference of one sheave (pulley) to twice the center distance between two equal diameter sheaves (pulleys) at a specified tension.

- The belt pitch length is normally the length at the belt pitch line. This line is generally located at the neutral axis near the cord line and varies with cross section and construction. The pitch of the belt and sheave is actually a theoretical point that relates to the more accurate, reliable, and useable effective diameter and effective length.

- This datum system defines specific sheave (pulley) and belt dimensions previously known as the pitch system for classical belts and sheaves. What were previously identified as pitch diameter or pitch length are now known as datum diameter or datum length. These are the new catalog identifiers which allow all belt and sheave manufacturers and users to use the same nomenclature.

- Belt Effective Length: The effective length of a belt is the length about the effective outside diameter of a sheave at a specified tension. The effective outside diameter of a sheave is measured where the groove top width is a dimension as specified by RMA, ASAE or SAE standards. The effective length is obtained by adding the effective outside circumference of one sheave (pulley) to twice the center distance between the two standard measuring sheaves (pulleys) at the standard measuring tension.

- Nominal Belt Length: The nominal length is used to refer to the length and cross section of a specific belt. For example, an A38 has a nominal length of 38 inches; a 4L440 has a nominal length of 44.0 inches; and a 3V300 has a nominal length of 30.0 inches. The nominal length is used for designation purposes and exists in name only.

Related post: Belt Length Acronyms (La, LE, Ld, Lp, Lw and Li)

When to use which diameter

The formulas have all remained the same, but this table from Gates makes it easier for everyone trying to figure out which belt diameters to measure:

| To Calculate | Previously Used | Now Use |

| Speed Ratio | Pitch Diameters | Pitch Diameters |

| Belt Speed | Pitch Diameters | Pitch Diameters |

| Horsepower Rating | Pitch Diameters | Pitch Diameters |

| Rim Speed | Outside Diameters | Outside Diameters |

| Center Distance | Pitch Diameter and Pitch Length | Datum Diameter and Datum Length |

| Belt Length (Datum) | Pitch Diameters | Datum Diameters |

| Center Distance Factor "h" | Pitch Diameters | Datum Diameters |

| Arc of Contact correction Factor "G" | Pitch or Outside Diameters | Datum, Pitch or Outside Diameters |

| Span Length | Pitch or Outside Diameters | Datum, Pitch or Outside Diameters |

How to measure classical V belts

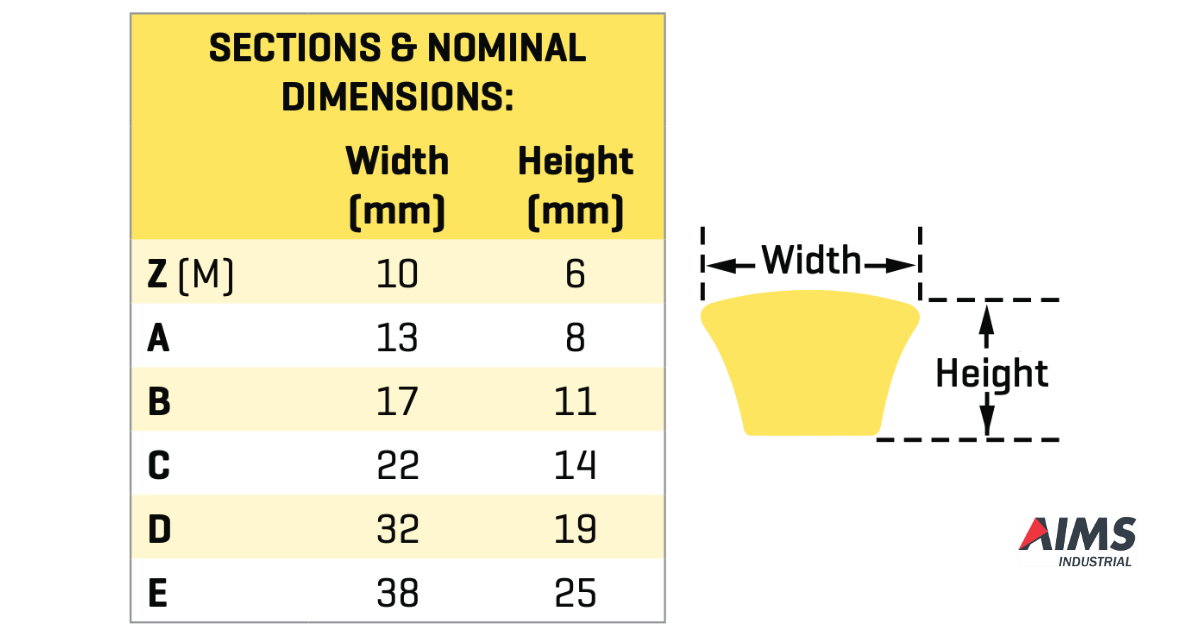

This refers to the original form of power transmission belts with a belt profile of M, Z, A, B, C, D & E.

It also refers to the cogged (notched) version of these belts, referred to as ZX, AX, BX & CX.

These belts are dimensionally the same as the wrapped belt but have cogging running perpendicular to the length, as per this image.

Classical belts are traditionally measured by internal circumference in inches.

Therefore, an A26 belt has an internal circumference of 26 inches.

A note of caution: Although rare, we have started to see occurrences of classical belts being marked by measures other than internal circumference, so it is worth double-checking the measurement of your belt if it is from a manufacturer that you don’t know.

Quality brands such as Gates, Carlisle and Opti are all measured by internal circumference.

If it is more convenient to measure the outside circumference, you can do that. Just DEDUCT the following for each size to find the internal circumference since, as you know, the outside circumference is greater than the internal.

- Z: 1”

- A: 2”

- B: 3”

- C: 4”

- D: 5”

- E: 6”

The above applies whether the belt is the wrapped or cogged version.

M section belts have a different profile with a very small difference between the internal and external circumference.

How to measure narrow section V belts

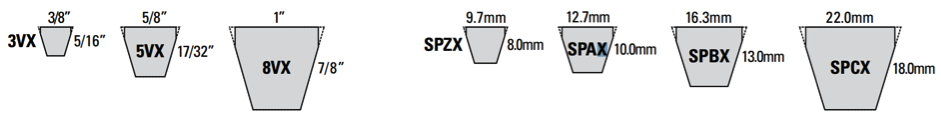

Narrow section belts include SPZ, SPA, SPB & SPC belts. It also includes their cogged equivalents, XPZ, XPA, XPB & XPC belts. (Some manufacturers refer to these as SPZX, SPAX, SPBX & SPCX.)

These belts are metric belts, but this section also discusses narrow section imperial V belts, which include 3V, 5V, 8V & 3VX, 5VX and 8VX belts.

Dimensions for the wrapped and cogged narrow section belt are as per this image:

Narrow section V belts are identified by their pitch length.

For example, an XPZ987 has a pitch length of 987 mm.

In order to calculate the pitch length of the belt, you must measure the inside length (circumference) and then ADD a figure, depending on section size, as listed below:

- SPZ: 13 mm

- SPA: 18 mm

- SPB: 22 mm

- SPC: 30 mm

It's different for imperial belts. As with the classical belts, these are measured and identified in inches according to their inside circumference. For example, a 3V400 has an internal circumference of 40.0 inches, and a 3V450 has an internal circumference of 40.5 inches.

Conclusion

Chances are you don’t have a belt measuring device so we find the handiest way to measure them is to clearly mark a starting point on the belt with a text and then use a dressmaker’s tape to measure slowly and carefully around the belt.

And we like to do it at least twice. To borrow from the carpenter’s golden rule: Measure twice and buy once!

Hopefully, this has helped you to identify the length of belt you need but, of course, if you’re still having a challenge, give us a call or send us an email and we’ll work with you to figure it out.

If you would like to read more about the various types of power transmission belts, Wikipedia has an excellent page that summarizes the various types of belts which have been using across the decades.

![]()

To borrow from the carpenter’s golden rule: Measure twice and buy once!

AIMS' Note on Safe Use of Belt-Driven Systems

- Power down: Before any inspection, maintenance, or adjustment, make sure to completely shut down the power to the machine and apply a lockout/tagout (LOTO) device to prevent accidental restarts.

- Right belt for the system: Keep in mind that v-belts (especially cogged / notched / wrapped belts) are different from synchronous /timing / ‘toothed’ belts. Some mistake the cogs for teeth but remember that cogged belts run on V-shaped pulleys that do not have teeth. Are you operating where flammable substances are present? Maybe you need fire-resistant anti-static (FRAS) belts – or maybe heat-resistant and oil-resistant belts will do. We compared them in this FAQ.

- Safe attire: Avoid loose clothing, jewelry and long hair that could get caught in the moving parts. Ensure proper fit of workwear without compromising comfort, dexterity and protection. Tie back long hair and secure loose items.

- Safeguards in place: Never operate a belt-driven system with the guards removed or bypassed. These guards are there for your protection.

- Maintenance and replacement: Regularly inspect belts and pulleys for wear and tear. Maintain proper belt tension and alignment as specified by the manufacturer. When replacing the belt, make sure you get the proper fit and measurement of the system. These accessories and maintenance kits (eg alignment tools, belt measurers, pulley gauge sets, spacers, tensioners etc) come in handy.

- Cleanliness: Keep the area around belt drives free of debris and clutter that could get caught or cause a fire hazard.

(Refer to our content library's sub-index of articles about belt-driven systems and electric motors for more information.)

.png)