Specifications

- AIMS SKU A0009728

- Brand Sutton Tools

- Model Number E5190400

- Barcode Number 9311963502441

- System of Measurement DIN6527K,Metric

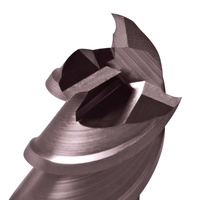

- Material Sub-Micron Grade Solid Carbide (VHM-ISO K40)

- Finish Aluminium Chromium Nitride (AlCrN)

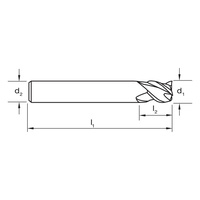

- Cutting Tip (mm) 4

- Overall Length (mm) 54

- Shank (mm) 6

- Flute Length (mm) 5

- Item Type N (finishing)

SKU: A0009728

Sutton E5190400 4 x 6mm 3 Flute Endmill - Solid Carbide VHM AlCrN - Short

Sutton 3 Flute Stub Endmill - R45 W - Short - Tecline

$33.23